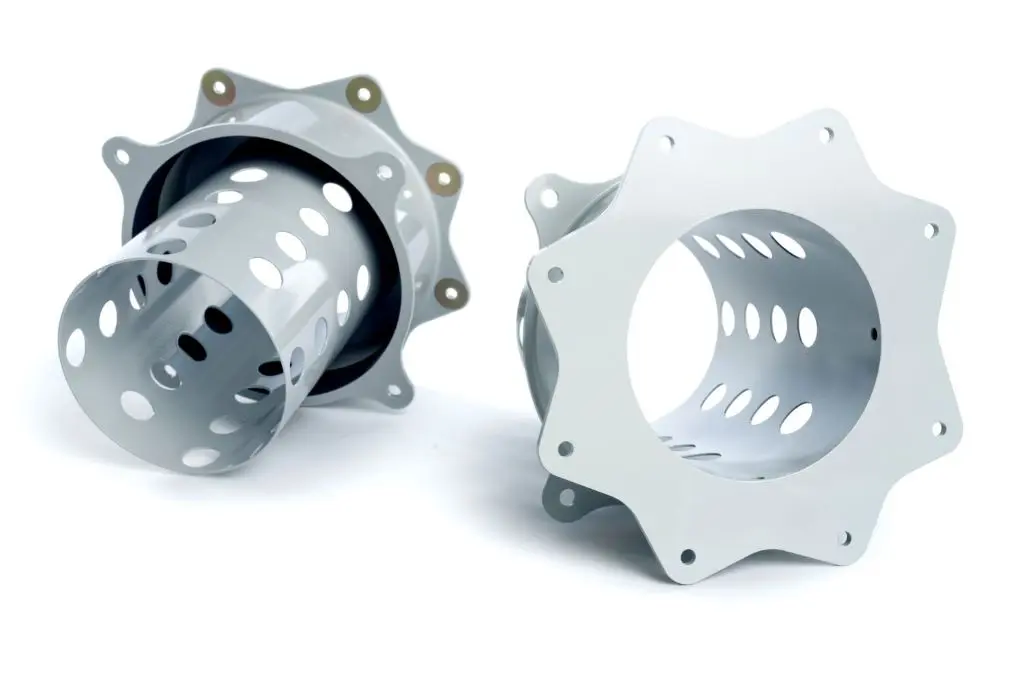

Sigma uses precision-engineering technology to produce a range of airframe sheet & machined details to meet the scope of the complex specifications and strict requirements of our customers.

Sheet & machined detail parts are singular items that start the form of the airframe structure and its associated systems, such as fluid conveyance and a range of cleats, brackets, ribs, adaptors, end fitting and more.

With over 40 years of experience, we supply profiled sheet details and machined components to major OEM and Tier 1 companies. Our integrated supply chain and additional manufacturing footprint in China also allows us to offer customers low-cost solutions for all stages of the product life cycle.

In addition, we continue to invest in modern CAD/CAM and CNC machine tool technology to ensure that we maintain the highest standards of quality while also providing our customers with a competitive offering.

Sheet Details

Across the UK & China, we have comprehensive sheet detail forming and manufacturing capabilities.

Capabilities

- 250 Tonne Dual action Hydraulic Presses

- Cold Forming

- CNC Router 3m x 1.5m

- Multiple press brakes

- Stretchers & Shrinkers

Applications

- Brackets

- Cable Supports

- C-Class

- Deep Drawn Pressings

- Direct Line Feed (DLF)

- Fairings & Shrouds

- Ribs & Intercostals

- Top Hat Sections

Machined Details

We have over 55 CNC machining centres in the business with access to a broad network of approved suppliers for associated support and non-core special-process.

CNC Turning

- CNC lathes, chuck or bar fed

- Live tooling with C and Y axes

- Max chuck diameter 10″ (250mm)

- Sliding head machines for higher volume production

- Tolerances to +/- 0,005mm (.012mm)

CNC Milling

- Upto 5 axis capability

- Max size 1000 x 1500mm

- Pallet change

- Tolerances to +/- 0,005mm

- Vertical and horizontal machining centres

Applications

- Adaptors

- Brackets

- Diffusers

- End Fittings

- Ferrules

- Intakes

- Plates

- Ribs

Contact Sigma

For more information or to find out how Sigma can work with you to meet your sheet & machined detail requirements, please contact our sales team.